What We Do

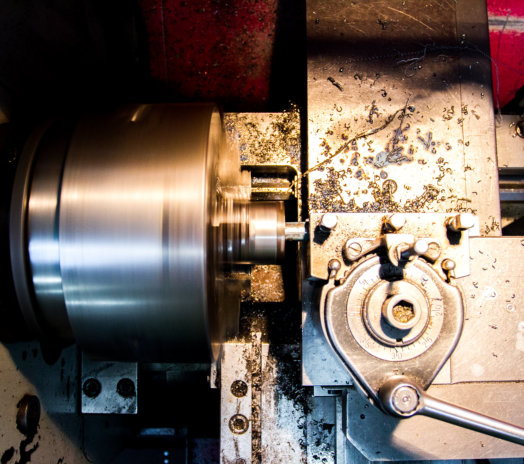

Turning

One of the key services offered by PRYMET Lubawa is the turning of steel components.

Below, we present several key elements of our machinery.

CLX450 V6 Turning Center

Max Turning Diameter: 400 Mm

Max Turning Length: 750 Mm

Spindle Bore: 80 Mm

Live Tooling (Enables Off-Center Milling and Drilling) Sub-spindle – Complete Machining of the Component from both Sides Y-axis

IEMCA Bar Feeder – Increased Efficiency in Series Production

CTX 310 Turning Center – Machining Parameters

Max Turning Diameter: 200 Mm

Max Turning Length: 450 Mm

Spindle Bore: 52 Mm

Live Tooling (Enables Off-Center Milling and Drilling) Tailstock

NEF-520K GILDEMEISTER Lathe

Heidenhain Cycle Control

Max Turning Diameter over Cross Slide: 290 Mm

Max Turning Diameter over Bed: 500 Mm

Max Turning Length: 850 Mm

Spindle Bore: 70 Mm

Conventional Lathes

TUR, TUM Lathes

Conventional Turning (Max Turning Diameter Ø 500 over Bed, Ø 300 over Cross Slide, Turning Length 2000 Mm)

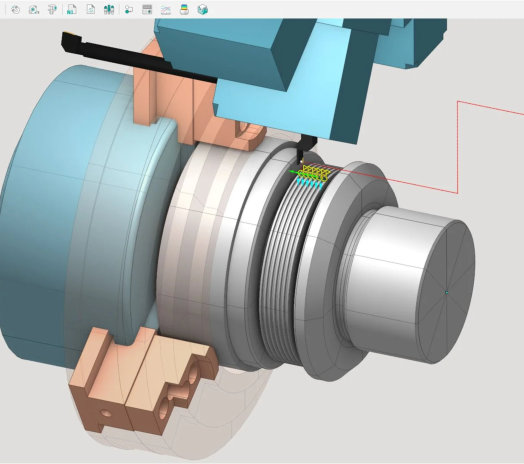

CAM Software for Lathes

Software that allows the technologist to generate a program for a CNC machine based on a digital 3D model of the component. The program generates tool paths based on the provided data.

Benefits:

Reduced Program Writing Time for Complex Tool Paths

Off-machine Machining Simulation Capability and Detection of Potential Collisions

Ability to Apply Machining Strategies that Reduce Tool Wear and Improve Work Efficiency

Ability to Define Paths and Programs that are Impossible to Program from the Machine Control Panel.

How We Work

Project Execution Process

1

Uzgodnienie

Agreement on key issues

regarding the order with the client.

regarding the order with the client.

2

Planowanie

Planning of the technological process

to ensure the best execution

of ordered parts.

to ensure the best execution

of ordered parts.

3

Produkcja

Material processing on specialized

machines to produce the finished component.

machines to produce the finished component.

4

Wysyłka

Handover of parts

for delivery to the client.

for delivery to the client.